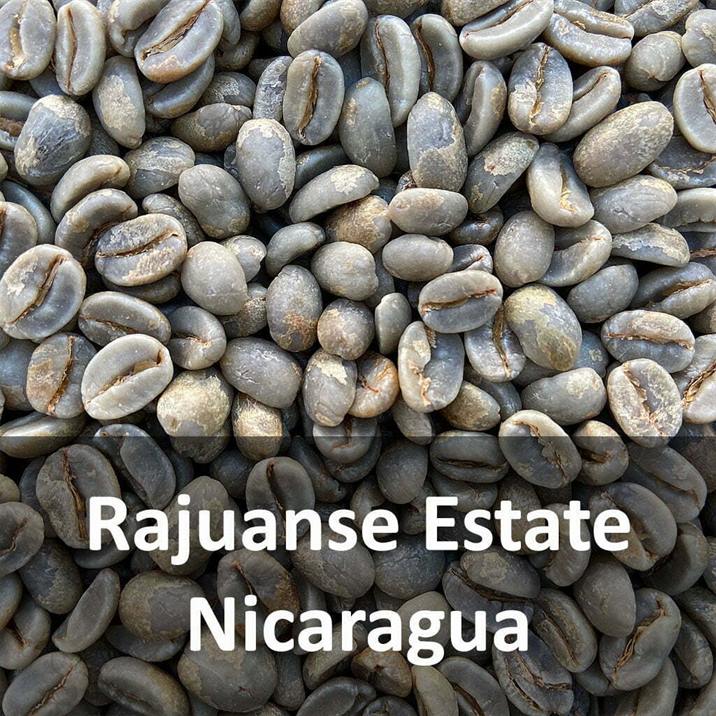

Green Nicaraguan Rajuanse Estate Honey processed coffee from Buena Esperanza sourced via Sevenoaks Trading Premium division.

Nicaraguan Coffee

Nicaragua has been growing coffee since 1790. Initially bought to the country as a curiosity by Catholic Missionaries, growing world-wide demand drove the government to create a subsidy. This subsidy was in place from 1979 until 1889.

Coffee was Nicaragua’s prominent export through dictatorship and communism until the early 1990s. However, after the coffee price crashed in 1999, the coffee sector was severely impacted. Compounding the crash was the devastation of Hurricane Mitch in 1998 and the drought over the turn of the millennium.

Since then, however, Nicaraguan coffee production has recovered, and quality has also improved.

Rajuanse Estates

This coffee is from the coffee farm based on Rajuanse Estate called Buena Esperanza. It is located in a privileged mountain valley in Matagalpa, Nicaragua. Originally it was part of a timber operation that was 2,818 Hectares in size and was owned by an American lumber operation dating back to the 1960s. In the early 1970s, it began its transformation into coffee farming, but during the late 1970s and 80s political events in Nicaragua led to national instabilities in many sectors, including farming in general. Currently, there is still one of the original workers in Buena Esperanza, Don Manuel, that planted the first coffee plants in Buena Esperanza, and he is our historian. It sits in a valley with many microclimates with different characteristics that treat different varieties of coffee plants. The elevation is 1100-1200 meters, with an average annual rainfall of 3000 mm. Buena Esperanza is certified by Rain Forest Alliance and Café Practice.1

The farm is 846 Hectares, and currently, 405 Hectares have coffee planted. Our master plan is to balance land usage, half coffee, and the other half is natural forest. We are combating local climate change and keeping local fauna. We have inventoried waters springs, creeks, and rivers. Waterways are being protected from deforestation and water pollution. We have an ongoing project with an organisation called Engineers Without Borders, to be able to supply neighbouring communities with potable water from water springs in our farm and making them part of the maintenance and better practices avoiding polluting existing waterways in their daily water usage.1

Rajuanse is committed to reforesting. Every year we look for gaps within the farm and fill them with local trees from our reforestation nursery. Shade and humidity retention have been imperative in the area.1

Success and Milling

In 2018, Buena Esperanza placed favourably in the finals of Cup of Excellence in Nicaragua with a washed Pacamara. This success meant it was time for a natural integration into the Specialty Coffee Segment. During the 2018/19 cycle, Rajuanse Estate incorporated a Specialty Coffee Team. The Specialty Coffee Teamwork in choosing different areas of the farm and different varieties which presented the utmost favourable conditions maximise the natural profiles of the coffee bean. The decision to select the drying process is determined at the mill and prepared immediately for transport to the off-site dry mill.

Coffees are milled at Sajonia Estate Coffee where there is a Specialty Coffee line just for Rajuanse in a controlled environment. Coffees here are processed using Natural, Honey or Washed methods. Rajuanse administrative offices are at Sajonia Estate where all our coffee is tracked from farm to export.

Honey Processing

We actually had a WhatsApp discussion with Ramiro to clarify their process here is an excerpt from that discussion:

When we do our special reserves, we pick our coffees only on the morning shift, and we select the lots to pick when we see a good Brix reading. Both the naturals and honeys are picked the same way(protocol) We pick only in the morning because we want to minimise time on the fields and try to get them to dry mill quickly.

The cherries are then passed on a mechanical siphon(cleaner), to sort any floaters and stay only with the dense cherries, and the cherries get washed. If it was naturals, they would go put in plastic crates and sent to the dry mill. Honeys continue to get de-pulped, and the beans get put in a plastic bag to make sure it retains its all its mucilage on the bean. Once we fill the bags, we send them over to dry mill. For honeys only the pulp is removed, no mucilage. Varieties play a key role in the amount of mucilage. In the case of Marsellesa it is a larger fruit than average and has lots of mucilage.

The farm calls in advance to the facility to have everyone ready to receive. There they are weight and put on raise racks. When put on the racks as they get there, they get placed so there is no more than an inch in height, so they dry evenly. The first couple of days, they get shuffled around by hand to make sure they get dried evenly.

During that process for each rack, as they are shuffled, starts getting purged, by selecting the beans that present uneven characteristics. This process might take 14 to 18 days, depending on the ambient wind and temperature.

Video of the shuffling

Here is a video Ramiro Sent to us. From the Facebook site (it is of the natural shuffling): (click here if no video appears here…

Details of Green Nicaraguan Rajuanse

| Region | Matagalpa, Nicaragua. |

|---|---|

| Farm | Buena Esperanza Farm on Rajuanse Estate. |

| Producer | Ramiro Ortiz. |

| Harvest | 2020. |

| Altitude | 1,100-1,200 masl. |

| Coffee Area | 405 Hectares of 846 Hectares. |

| Cultivar | Arabica Marsellesa |

| Processing | Honey (see details above) |

| Packaging | Grain Pro with Hessian. |

| Characteristics | A medium mouth-feel with caramel nuts as tasting notes. |

| Sevenoaks Cupping score | 85 |

| FOB Price PAID | not available |

| Certifications | RFA |

Sources:

1 Marketing material from Sevenoaks.

2 Conversation with Ramiro.

Reviews

There are no reviews yet.